Hydrofluoroether (HFE) is a highly effective and environmentally friendly cleaning solution widely used in electronics cleaning, computers cleaning, and industrial cleaning services. Due to its low surface tension, chemical stability, non-flammability, and low toxicity, it has become a preferred alternative to traditional cleaning products such as isopropyl alcohol (IPA).

HFE-based cleaning methods ensure proper cleaning while reducing exposure to hazardous materials and minimizing cross contamination. The ability of HFE to quickly evaporate without leaving residues makes it ideal for regular cleaning, deep cleaning, and maintenance in industrial environments.

HFE is widely used across industries, including semiconductors, aerospace, automotive, healthcare, and electronics manufacturing. Whether in manual cleaning or automated clean processes, it ensures that critical components remain cleaned and disinfected, improving operational efficiency and keeping systems running smoothly.

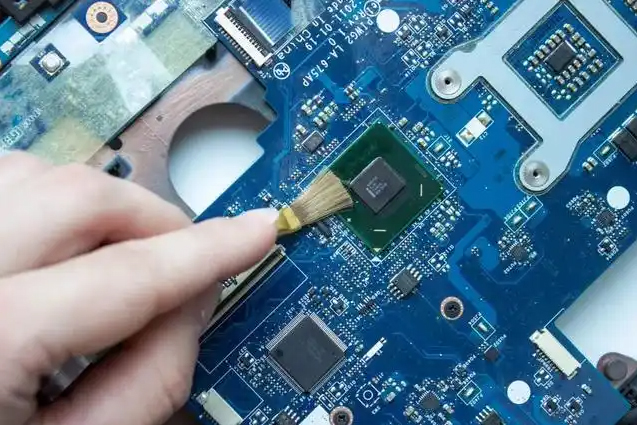

HFE plays a crucial role in electronics cleaning, where high precision and contamination control are required. It is used for cleaning delicate electronic components, printed circuit boards (PCBs), and semiconductor parts without leaving residues or damaging sensitive materials.

In electronics cleaning, removing flux residues, oils, and dust is essential to ensure circuit reliability. HFE effectively dissolves flux residues, providing a high-purity cleaning solution for PCB manufacturing and semiconductor assembly.

Printed Circuit Boards (PCB) Cleaning – Removes flux and solder residues using advanced cleaning methods

Semiconductor & Microelectronics Cleaning – Ensures contamination-free production by preventing bacteria and viruses buildup

Hard Disk Drive Cleaning – Keeps HDD components dust-free for proper cleaning

To prevent recontamination, compressed air to blow away particles is commonly used before and after the HFE cleaning process.

HFE-based cleaning products are widely used in computers cleaning, particularly in data centers, IT maintenance, and electronics repair services. Keeping computer components clean is essential for ensuring smooth operation and longevity.

Dust buildup on heat sinks and cooling systems reduces their efficiency, leading to overheating and system failures. HFE provides an effective cleaning solution by removing thermal grease and debris without damaging delicate components.

Cooling System Cleaning – Removes dust and contaminants, ensuring systems are running smoothly

Keyboard & Touchscreen Cleaning – Offers proper cleaning without affecting sensitive surfaces

Optical Lens & Sensor Cleaning – Protects cameras and displays from dirt accumulation

Many cleaning services use compressed air to blow away loose debris before applying HFE-based cleaning methods to prevent damage from excessive moisture.

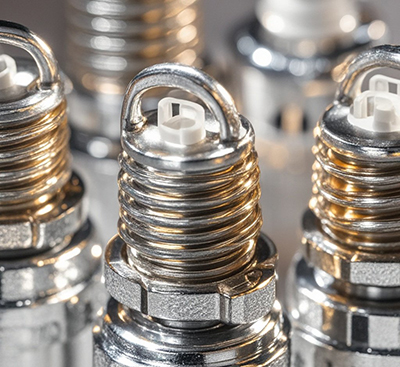

HFE is extensively used in industrial cleaning services for metal parts maintenance, machinery cleaning, and automotive component degreasing. In automotive and aerospace industries, where precision is crucial, HFE ensures deep cleaning without corroding metals or leaving conductive residues.

Removing oil, grease, and carbon deposits is essential for vehicle performance. Traditional solvents such as isopropyl alcohol (IPA) and petroleum-based cleaners often pose safety and environmental risks. HFE provides a hazard-free alternative that is both effective and environmentally friendly.

Carburetor & Fuel Injector Cleaning – Eliminates fuel deposits without damaging metal surfaces

Brake System Cleaning – Ensures precision cleaning without affecting brake pads and sensors

Engine Part Cleaning – Keeps mechanical components running smoothly

Proper personal protection equipment (PPE) should be used during manual cleaning to avoid prolonged exposure to cleaning products in an industrial environment.

Avionics Cleaning – Ensures contamination-free clean processes for sensitive instruments

Satellite & Optical Instrument Cleaning – Removes dust and micro-particles that can interfere with performance

Robotics & Automation Cleaning – Keeps robotic arms and moving parts free from grease buildup

Regular cleaning services using HFE-based cleaning solutions help maintain a clean industrial environment while reducing the risk of hazardous materials exposure.

HFE-based cleaning solutions are also used for medical devices, laboratory equipment, and critical industrial environments where deep cleaning and contamination control are essential.

Medical devices require proper cleaning to prevent infections and ensure operational efficiency. HFE is used in manual cleaning and automated systems to ensure surfaces are cleaned and disinfected.

Endoscope & Surgical Instrument Cleaning – Prevents bacteria and viruses contamination

Spectrometer & Microscopy Cleaning – Removes organic residues from optical lenses

X-ray & Diagnostic Equipment Cleaning – Ensures dust-free operation in hospitals

Regular cleaning services using HFE-based cleaning methods are essential in industries where contamination control is critical. These include cleanrooms, semiconductor fabrication plants, pharmaceutical facilities, and high-tech manufacturing environments.

Deep Cleaning for Manufacturing Facilities – Reduces risk of bacteria and viruses buildup

Preventing Cross Contamination in Electronics Assembly – Ensures all surfaces are cleaned and disinfected

Routine & Regular Cleaning in Industrial Environments – Keeps production equipment running smoothly

By using proper cleaning solutions along with compressed air to blow away contaminants, industries can maintain a clean industrial environment and reduce downtime.

Hydrofluoroether (HFE) is a highly effective cleaning agent used in electronics cleaning, computers cleaning, and industrial cleaning services. Its unique properties make it an excellent alternative to traditional solvents such as isopropyl alcohol (IPA), ensuring proper cleaning while minimizing risks associated with hazardous materials.

From deep cleaning in medical environments to regular cleaning in industrial settings, HFE provides a safe, efficient, and eco-friendly solution for various cleaning needs.

Contact: Tony Li

Phone: +86-13263299644

Tel: +86-13263299644

Email: sales@ecoviaet.com

Add: No 3 Youyi Road,Tangshan,Huantai,Zibo,China

We chat