Min. Order: 1 Piece Transport Package: According to Customer′s Requirements Payment Terms: L/C, T/T, D/P, Western Union, Paypal, Money Gram

Price:Negotiable

During the enameled wire production process, a certain amount of organic waste gas is generated. Its main components are benzene, toluene, xylene, non-methane total hydrocarbons, organic solvents, etc., which have a certain impact on the surrounding environment. Source of volatile organic compounds: Organic solvents, mainly triphenyl (benzene, toluene, xylene), are used to dilute paint to achieve a smooth and beautiful surface. However, organic solvents are highly volatile and cannot adhere to the surface of an object with paint for a long time. , all will be released during the spraying and drying process. It is colorless and diffuses in the atmosphere with the flow of air. It can be breathed by the human body or directly act on the human body, causing damage to various organs of the human body, and also causing direct damage through the skin.

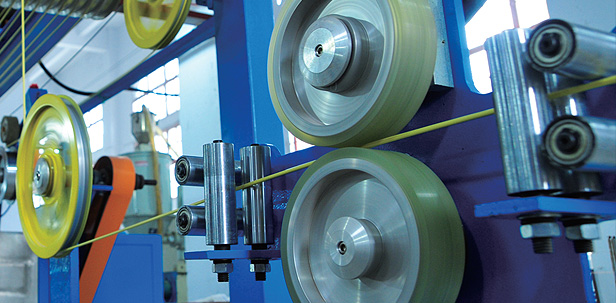

A specialized catalyst was developed based on the production process characteristics of enameled wire. This product is manufactured with a special coating formula and uses cordierite honeycomb ceramics with unique pore structures as the carrier. It features excellent thermal shock resistance, low gas flow resistance, a wide space velocity range, and long durability, making it suitable for applications such as enameled wire and color steel plate production lines.

VOCs sources: resin, polyurethane paint, organic solvents

VOCs production process: coating and drying

VOCs components: benzene series, phenols, alcohols, esters, etc.

VOCs concentration: 3000-8000mg/m³

Contact: Tony Li

Phone: +86-13263299644

Tel: +86-13263299644

Email: sales@ecoviaet.com

Add: No 3 Youyi Road,Tangshan,Huantai,Zibo,China

We chat