Metal ethylene removal catalysts are mainly used in scenarios requiring high precision ethylene removal and air purification due to their efficient catalytic oxidation performance. Precious metal catalysts have low onset temperatures and high conversion efficiencies for the catalytic oxidation of ethylene. The catalytic oxidation of ethylene by noble metal catalysts has a low starting temperature and high conversion efficiency. It maintains stable performance over a long period of time, and is suitable for scenarios requiring continuous ethylene removal. The reaction products are mainly carbon dioxide and water, without secondary pollution.

Ethylene removal catalysts are used in a large number of applications in the following industries:

1. Fruit and vegetable preservation warehouses

In large fruit and vegetable preservation warehouses, where high ethylene concentrations accelerate the ripening and spoilage of fruits and vegetables, air purification equipment with an integrated ethylene removal catalyst is used to catalyze the oxidation of ethylene to carbon dioxide and water at low temperatures. For example, in apple, banana or kiwi storage, ethylene removal catalysts keep ethylene concentrations below 1 ppm for long periods of time, effectively extending shelf life.

2. Aerospace and submarine environmental gas purification

In the confined environments of aerospace vehicles (e.g. space stations) or submarines, the accumulation of ethylene can have an impact on crew health and plant experiments. Ethylene removal catalysts are integrated into gas cycle purification systems to remove ethylene and other volatile organic compounds (VOCs) through low-temperature catalytic oxidation, and are used by NASA and others in space station plant experiments to ensure that ambient ethylene concentrations are extremely low to support normal plant growth.

3. High-end fruit and vegetable transportation (cold chain logistics)

Inside refrigerated cars or containers in long-distance transportation, ethylene concentrations that cannot be effectively controlled can lead to a decline in the quality of fruits and vegetables. The use of ethylene removal catalyzed ethylene removal devices in cold chain transportation allows for efficient operation at low temperatures (e.g. 0-10°C). For example, containers exporting tropical fruits such as bananas or avocados are equipped with such a catalytic purification system to ensure that the cargo arrives in optimal ripeness.

4. Greenhouse gas management

Ethylene in greenhouses not only affects plant growth, but may also affect the effectiveness of the CO2 fertilization system in the greenhouse. Greenhouses use ethylene removal catalysts to remove ethylene from the air in real time. High-end flower farms (e.g. orchids and tulips) use palladium-based catalytic converters to ensure that flowers are grown at low ethylene concentrations, improving quality and flowering time.

5. Laboratory Environmental Controls

Some precision chemical or biological experiments are sensitive to ethylene and other contaminants, such as calibration of gas detection equipment or plant metabolism experiments. Laboratory air purification equipment is equipped with ethylene removal catalysts to ensure that ethylene concentrations in the laboratory environment are maintained at very low levels. Laboratories used to study plant hormone reactions utilize ethylene removal catalysts to maintain clean air.

6. Medical Air Purification

In medical environments such as neonatal care units, ethylene gas can affect the health of infants. Some high-end air purification systems use precious metal catalysts to remove ethylene and other harmful volatiles, especially in environments with high precision purification requirements.

7. Industrial Ethylene Exhaust Treatment

In chemical, petrochemical and other industrial processes, the exhaust gas containing low concentration of ethylene needs to be discharged in compliance with the standard.

Palladium-based or platinum-based catalysts are used in factory exhaust gas treatment plants to efficiently decompose ethylene to harmless substances at low temperatures. For example, precious metal catalyst modules are often integrated into ethylene off-gas treatment plants in plastics production plants.

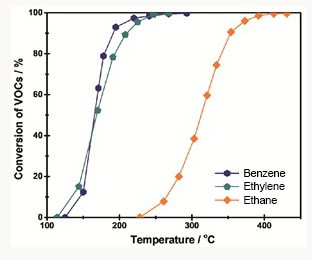

Dveloped with cold storage preservation technology, this catalyst effectively removes ethylene gas and other VOCs. It is widely used in cold storage ethylene removal and carbon dioxide dehydrocarbon purification.

Contact: Tony Li

Phone: +86-13263299644

Tel: +86-13263299644

Email: sales@ecoviaet.com

Add: No 3 Youyi Road,Tangshan,Huantai,Zibo,China

We chat