Min. Order: 1 Piece Transport Package: According to Customer′s Requirements Payment Terms: L/C, T/T, D/P, Western Union, Paypal, Money Gram

Price:Negotiable

Emissions of volatile organic compounds (VOCs) are one of the major contributors to air pollution. VOCs come from different sources, mainly from waste gas emissions from various industrial production processes. It will lead to serious atmospheric environmental problems and deny the sustainable development of social economy.

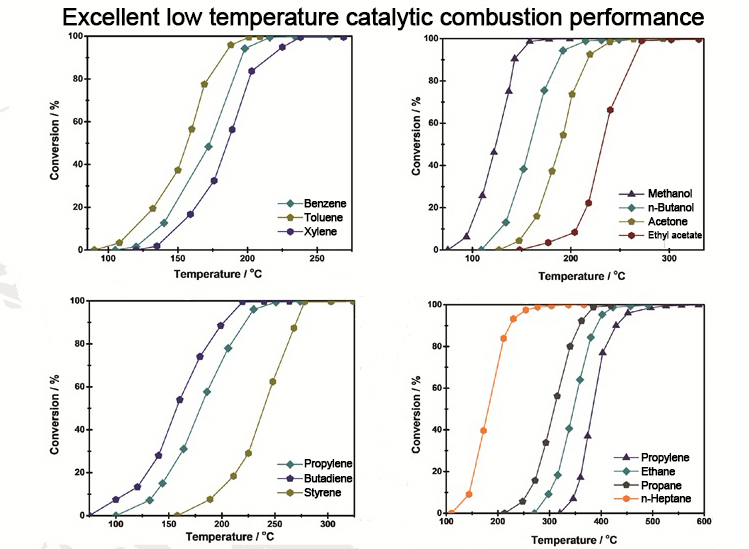

Catalytic oxidation, which oxidizes VOCs into CO2, water and other relatively small dissolved compounds, is one of the most effective, economical and feasible technologies.

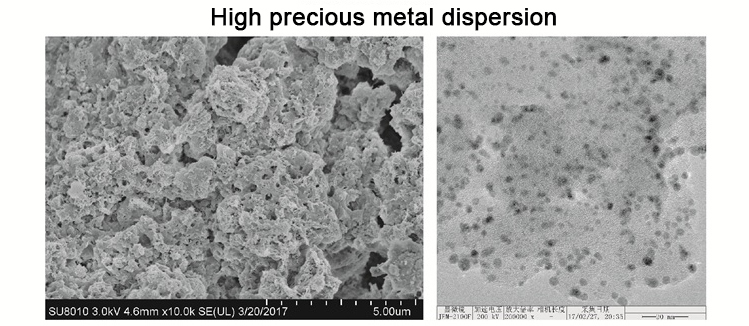

Oxidation catalysts, especially precious metal catalysts, are widely used in the treatment of volatile organic compounds (VOCs) through catalytic oxidation. These catalysts are known for their excellent reactivity, stability, strong resistance to poisoning, and ease of regeneration, making them an ideal choice for VOC removal.

In the process of catalytic oxidation, oxidation catalysts facilitate the conversion of harmful VOCs into safer compounds like carbon dioxide (CO₂) and water (H₂O), typically at lower temperatures and under mild conditions. This process is particularly effective for industries that generate organic exhaust gases, as it provides an efficient way to mitigate pollution.

Our VOC removal catalysts are specifically designed to offer:

Low activation temperatures: Enabling effective VOC oxidation even at relatively low temperatures, which contributes to energy savings.

High thermal stability: Ensuring long-lasting performance even under high temperature conditions, making them suitable for industrial environments.

Strong anti-coking properties: Preventing catalyst deactivation due to the buildup of carbon residues, a common issue in VOC oxidation processes.

These oxidation catalysts are widely applied across numerous industries, including:

Pharmaceutical: For the removal of VOCs generated during the production of drugs and chemicals.

Printing and Coating: In the elimination of solvent-based emissions that contribute to environmental pollution.

Electronics: For controlling VOC emissions during the manufacture of electronic components.

Oil and Gas Storage: Where VOCs are often released during storage and transportation of petroleum products.

Petrochemical and Chemical Industries: In processes that produce significant amounts of VOCs as by-products, such as refining, polymer production, and chemical synthesis.

Our oxidation catalysts are tailored to meet the specific needs of different industries and VOC characteristics. VOCs can vary widely, including S-VOCs (sulfur-containing VOCs), N-VOCs (nitrogen-containing VOCs), long-chain hydrocarbons, and aromatic compounds. We provide customized solutions based on the specific exhaust gas profile to ensure maximum removal efficiency.

| Item | Honeycomb Catalyst | Spherical Catalyst |

| Precious Metal Content | 150-800/m³ | 400-1500/m³ |

| Recommended Space Velocity | 5000-20000h⁻¹ | 5000-20000h⁻¹ |

| Applicable Concentration | ≤8000mg/m³ | ≤10000mg/m³ |

| Application Industries | Pharmaceutical, spraying, electronics, oil and gas storage, petrochemical chemical, etc. | Cold storage preservation, low carbon alkane purification, Instrumentation and other industries |

| Customizable Items | Size specifications, precious metal content | Particle size、Precious metal content |

| Type | Typical Sizes | Other Sizes |

| Pellet | Diameter 1 mm | All sizes from pellet 1mm to 9mm can be produced, such as pellet diameter 2mm, 4mm, etc. |

| Diameter 3 mm | ||

| Diameter 5 mm | ||

| Diameter 9 mm | ||

| Granule | 4-8 Mesh | Different granule sizes can be produced as your request. |

| 8-14 Mesh | ||

| 6-12 Mesh | ||

| 10-16 Mesh | ||

| 12-20 Mesh | ||

| Powder | Fine than 80 Mesh | Finer than 80 Mesh |

| Spherality Ball | Diameter 2mm-10mm | Produced as your request. |

| Honeycomb | 100x100x50mm | Produced as your request. |

| Customized | We offer consultations regarding the trial manufacture and contract of catalysts that have been customized in accordance with customer needs (Pt content changes, Pd content, etc.). | |

We offer various types of catalysts to suit different VOC removal needs:

Cordierite honeycomb: This type offers a large surface area and low thermal expansion, making it ideal for high-volume VOC treatment.

Metal honeycomb: Known for its durability and high surface area, it is commonly used in harsh industrial environments.

Spherical: A versatile option with good resistance to thermal shock, suitable for processes requiring high flow rates.

Granular: Providing high packing density, these catalysts are ideal for fixed-bed reactors.

Felt: Used in specialized applications where flexibility and adaptability are needed.

The use of oxidation catalysts in catalyctic oxidation for VOC removal is an effective and environmentally friendly solution for industries dealing with organic exhaust gases. By selecting the right catalyst based on the VOC profile and operational conditions, businesses can reduce harmful emissions, comply with environmental regulations, and enhance overall sustainability. Our customized catalyst solutions offer exceptional performance, tailored to the unique needs of each industry, ensuring optimal VOC removal and long-term operational efficiency.

Operation precautions

1. Before each use of the catalyst, it is necessary to use air without exhaust gas at a temperature of 250~300°C .Preheat for more than half an hour.

2. The normal working temperature range of the catalyst is 250~600°C, in order to ensure that the catalyst runs in the best state, please control the appropriate catalyst inlet temperature, organic waste gas concentration, catalyst airspeed and other parameters according to the specific application environment.

3. Avoid the introduction of dust as much as possible to avoid catalyst poisoning or blocking of catalyst pores.

4. The maximum withstand temperature of the catalyst is 700°C, so as to avoid the catalyst being at a high temperature above 700°C for a long time.

5. When stopping, the exhaust gas source should be cut off first, and it is absolutely forbidden to cut off the heating of the catalyst bed.After the power supply and the temperature is lower than the normal operating temperature, the exhaust gas is introduced. After cutting off the exhaust gas source, continue to turn on the fresh air at 300~400°C and stop the car for half an hour.

6. If it is found that the performance of the catalyst is due to the insufficient temperature of the catalyst bed or the concentration of exhaust gas is too high.If the performance of the catalyst decreases, or in case of sudden power failure, it is recommended to use 500°C hot air to preheat for 1~2 hours when the machine is turned on again, which can be restored or partially restored chemical activity.

7. Some substances will poison the catalyst, such as heavy metal lead, organic or inorganic sulfides, halides, etc., which will cause catalyst inactivation, and it should be forbidden to introduce them during use substances.

Contact: Tony Li

Phone: +86-13263299644

Tel: +86-13263299644

Email: sales@ecoviaet.com

Add: No 3 Youyi Road,Tangshan,Huantai,Zibo,China

We chat