Min. Order: 1 Piece Transport Package: According to Customer′s Requirements Payment Terms: L/C, T/T, D/P, Western Union, Paypal, Money Gram

Price:Negotiable

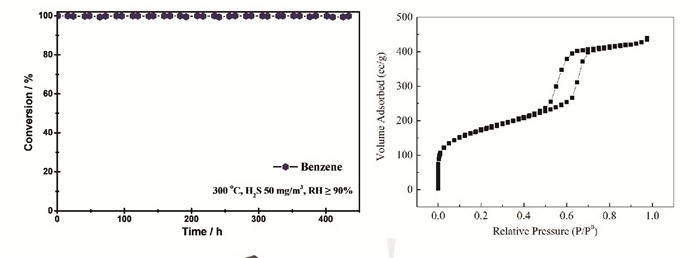

Sulfur is a common catalyst poisoning substance that can reduce the catalytic performance and lifespan of catalysts. Sulfur poisoning typically manifests as a decline in catalyst activity, deterioration in selectivity, and decreased stability. The catalyst surface may have multiple adsorption sites, which sulfur compounds can occupy, competing with reactants for adsorption. This competition prevents the reactants from reacting on the catalyst. Sulfur compounds can form inactive species on the catalyst surface, blocking active sites and reducing the contact between reactants and the catalyst surface, thereby hindering the catalytic reaction. Sulfur compounds may also form S-M bonds with metal ions on the catalyst surface, causing structural damage to the catalyst and resulting in the loss of activity. Gas rich in hydrogen sulfide can dissolve in water in the presence of moisture, forming hydrosulfuric acid. This acid can react with metal equipment and pipelines to generate corresponding metal sulfides, leading to equipment corrosion. The degree of corrosion increases with the partial pressure of hydrogen sulfide in the gas, and in severe cases, it may cause stress corrosion cracking in the weld areas of equipment.

Sulfur-Resistant VOCs Catalyst, made with high-specific-surface-area rare earth powder material with optimized surface acidity and oxygen vacancy, efficiently treat VOCs with high sulfur content (up to 50mg/m³) at lower temperatures (around 300°C). Post-treatment gas exhibits weak acidity, causing minimal or no corrosion to equipment.

Item | Sulfur-Resistant VOCs Catalyst |

Common Specification | 150×150×50mm |

Recommended Space Velocity | ≤2000h⁻¹ |

Concentration Range | ≤8000mg/m3 |

Application Conditions | Total sulfur ≤50 mg/m³;Inlet temperature >320°C |

Customizable Items | Size specifications |

Contact: Tony Li

Phone: +86-13263299644

Tel: +86-13263299644

Email: sales@ecoviaet.com

Add: No 3 Youyi Road,Tangshan,Huantai,Zibo,China

We chat