Dimethicone (PDMS) is a versatile organosilicon polymer well known for its exceptional chemical stability, low surface tension, thermal resistance, and biocompatibility. Its viscosity varies across a wide range, offering tailored solutions across different industrial uses.

Dimethicone (also known as polydimethylsiloxane or PDMS) is not classified into broad categories like "low," "medium," or "high" in a formal, standardized system across all industries. Instead, it is typically classified and specified by its nominal kinematic viscosity.

Viscosity Value: Dimethicone is available in a wide range of specific viscosities. Manufacturers produce and sell different grades identified by their viscosity number.

Unit: The standard unit used is centistokes (cSt).

Standard Temperature: Viscosity is temperature-dependent, so it's measured at a standard temperature, usually 25°C (77°F).

Therefore, Dimethicone is classified directly by its numerical viscosity value in cSt at 25°C. You will see products listed as:

Dimethicone 5 cSt

Dimethicone 20 cSt

Dimethicone 100 cSt

Dimethicone 350 cSt (a very common grade in cosmetics)

Dimethicone 500 cSt

Dimethicone 1000 cSt

Dimethicone 10,000 cSt

Dimethicone 60,000 cSt

And many other values, ranging from less than 1 cSt up to several hundred thousand cSt or even higher (sometimes referred to as silicone gums at very high molecular weights/viscosities).

Based on the nature of Dimethicone, as a silicone polymer fluid, several factors influence its viscosity:

Molecular Weight / Polymer Chain Length: This is the primary factor determining the inherent viscosity of a specific Dimethicone grade.

Dimethicone consists of repeating -(CH₃)₂SiO- units.

Longer polymer chains (higher molecular weight) lead to increased entanglement between molecules.

This entanglement makes it harder for the chains to slide past each other, resulting in higher resistance to flow, i.e., higher viscosity.

Manufacturers control the polymerization process to produce specific average chain lengths, which correspond to the different viscosity grades available (e.g., 5 cSt, 350 cSt, 10,000 cSt).

Temperature: This is the most significant external factor affecting the viscosity of a given Dimethicone grade.

Like almost all liquids, Dimethicone's viscosity decreases as temperature increases. Higher temperatures provide molecules with more kinetic energy, allowing them to overcome intermolecular forces and flow more easily.

Conversely, viscosity increases as temperature decreases.

While temperature-dependent, silicone fluids like Dimethicone generally exhibit a relatively smaller change in viscosity with temperature compared to many hydrocarbon oils of similar viscosity, making them stable over a wider temperature range.

Shear Rate (Less Significant for Common Grades):

Viscosity can sometimes depend on how fast the fluid is being sheared or moved (e.g., stirred, pumped, spread).

Most standard Dimethicone fluids (especially lower to medium viscosities like up to 1000 cSt) behave as largely Newtonian fluids under typical conditions. This means their viscosity remains relatively constant regardless of the shear rate applied.

However, very high molecular weight Dimethicones (silicone gums) or highly filled silicone systems can exhibit non-Newtonian behavior, often shear-thinning (viscosity decreases at higher shear rates).

Pressure (Minor Factor):

Viscosity generally increases slightly with increasing pressure, as molecules are forced closer together.

However, for most common applications of Dimethicone (cosmetics, personal care, food processing, common industrial uses), the effect of pressure on viscosity is negligible compared to the effects of molecular weight and temperature.

In summary, the specific grade (and therefore inherent viscosity) of Dimethicone is determined by its molecular weight/chain length. Once you have a specific grade, its actual viscosity during use will be most significantly affected by the ambient temperature.

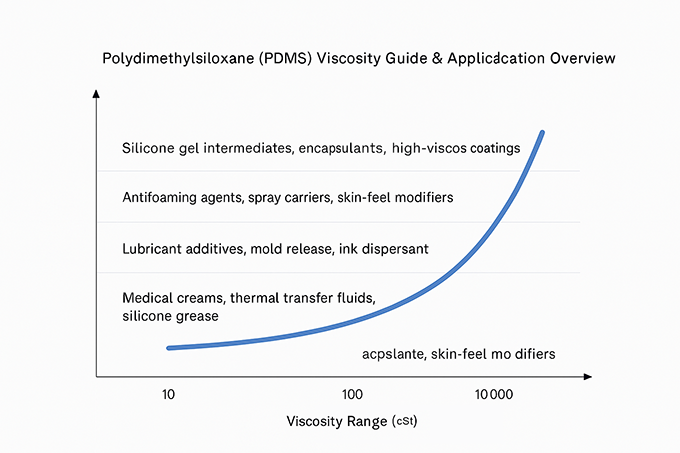

| Viscosity Range (cSt) | Application Area |

|---|---|

| 5–50 | Antifoaming agents, spray carriers, skin-feel modifiers |

| 100–500 | Lubricant additives, mold release, ink dispersants |

| 1000–10,000 | Medical creams, thermal transfer fluids, silicone greases |

| 60,000–100,000+ | Silicone gel intermediates, encapsulants, high-viscosity coatings |

Structure: [-Si(CH₃)₂O-]ₙ

Viscosity Range: 5 ~ 1,000,000+ cSt

Appearance: Colorless transparent liquid (low/mid viscosity), semi-flow or gel (high viscosity)

Density (25°C): 0.96–0.98 g/cm³

Refractive Index (25°C): 1.400–1.410

Customizable End Groups: -OH, -CH₃, -Vinyl

1. Define Your Application & Required Properties FIRST:

What will you use it for? (e.g., Skin cream, hair serum, mold release agent, lubricant, antifoam, damping fluid). This is the most critical step.

What properties are essential?

Spreadability/Feel: Lower viscosities (e.g., 5-100 cSt) spread easily and feel lighter, less greasy. Higher viscosities (e.g., 1,000-100,000+ cSt) spread less easily and feel heavier, providing more cushion or drag.

Film Formation/Barrier: Higher viscosities form thicker, more substantive, and potentially more occlusive films (good for barrier creams, protectants).

Lubrication: The optimal viscosity depends heavily on the specific lubrication needs (load, speed, materials).

Volatility: Very low viscosities (e.g., <10 cSt) can be somewhat volatile (evaporate), which might be desirable (e.g., quick-drying sprays) or undesirable.

Damping: Higher viscosities provide more damping force.

2. Specify the Exact Viscosity (in cSt @ 25°C):

Don't just ask for "low" or "high" viscosity. Use the specific centistokes (cSt) value measured at 25°C.

Research typical viscosities used in similar applications. Common cosmetic grades include 50, 100, 350, 500, and 1000 cSt. Industrial uses span a much wider range.

If unsure, consider starting with a common medium viscosity (like 350 cSt for personal care) and experimenting, or testing samples of a few different grades (see point 6).

3. Choose the Correct Grade/Purity:

Cosmetic Grade (INCI: Dimethicone): Meets standards for use in personal care products (e.g., USP/NF - United States Pharmacopeia/National Formulary). Lower levels of impurities. This is essential if it's for products applied to the skin or hair.

Food Grade: Meets specific regulations for incidental food contact or use in food processing (e.g., as an antifoam). Check FDA regulations if applicable.

Technical/Industrial Grade: Suitable for general industrial applications (lubricants, mold release, hydraulic fluids) where cosmetic or food purity is not required. Often less expensive.

Medical Grade: Requires stringent testing and biocompatibility for medical device applications.

4. Determine Required Quantity & Packaging:

Quantities range from small bottles (100mL, 500mL, 1L for lab/DIY) to pails (5 gallons), drums (55 gallons), and totes (275 gallons) for industrial use.

Suppliers often specialize in different scales (lab suppliers vs. bulk chemical distributors).

Consider your storage space and handling capabilities when choosing packaging. Larger containers are cheaper per unit but harder to handle.

5. Select Your Supplier Carefully:

Reputable Distributors: Look for established chemical distributors or suppliers specializing in silicones or cosmetic ingredients (if applicable). Examples in the US include major chemical distributors or more specialized players.

Online Retailers: For smaller quantities (lab/DIY), sites specializing in lab supplies or cosmetic ingredients are good options.

Check: Reputation, reliability, lead times, shipping costs, technical support availability.

6. Request Documentation:

Safety Data Sheet (SDS): Essential for safe handling and storage information. Required by regulations.

Technical Data Sheet (TDS): Provides detailed physical properties, including viscosity range, specific gravity, refractive index, etc.

Certificate of Analysis (CoA): Crucial for quality control, especially in manufacturing. It confirms the specific batch meets specifications, including the viscosity range. Ensure the viscosity on the CoA matches your requirements.

7. Obtain Samples for Testing:

Whenever possible, especially for new applications or formulations, request small samples of the viscosities you are considering before placing a large order.

Test the sample in your actual application or formulation to confirm it provides the desired performance and sensory characteristics (feel, spreadability). How a specific viscosity behaves can vary slightly depending on the other ingredients in a formula.

8. Compare Costs and Consider Blending:

Compare prices per unit (e.g., $/kg or $/gallon) between suppliers for the same viscosity and grade.

Factor in shipping costs.

Consider shelf life – don't over-order if you won't use it promptly.

Blending: If you need an intermediate viscosity not readily available, or want to fine-tune properties, you can blend two different viscosities of Dimethicone. However, achieving a precise target viscosity requires calculation (logarithmic mixing rules often apply) and thorough testing.

By considering these points, you can make a more informed decision when purchasing PDMS/Dimethicone tailored to your specific needs based on its viscosity. Remember that application requirements should always drive your choice.

Polydimethylsiloxane has good chemical stability and physical properties, and its viscosity is also one of the important parameters affecting its properties and application areas. PDMS with different viscosities are applied in different fields and have unique performance performance. Understanding the difference of Dimethicone viscosity and its influence will help us to better select and apply this silicone compound.

Ecovia supplies Dimethicone (Dimethyl Silicone Fluid) grades from 5cSt to over 1,000,000cSt with customizable end groups and packaging options, meeting the high-performance needs of global buyers in the chemical industry.

Contact: Tony Li

Phone: +86-13263299644

Tel: +86-13263299644

Email: sales@ecoviaet.com

Add: No 3 Youyi Road,Tangshan,Huantai,Zibo,China

We chat