Fumed Silica plays a vital role in the production and application of coatings. Fumed silica (fumed silica) can not only be used in paints and coatings as rheological additives and dispersants, but also has the functions of anti-settling, anti-caking, matting and anti-corrosion. In the field of coatings is constantly practiced and widely used, and occupies a place, the following briefly introduces the fumed silica and coatings can not say the secret of the role of the mechanism.

The surface of untreated fumed silica contains a large number of hydroxyl groups, which are very easy to form a uniform three-dimensional mesh structure in the oily system through the hydrogen bonding between each other, which can increase the viscosity of the coating. This three-dimensional network structure will be destroyed by mechanical shear, so that the viscosity of the coating will be reduced to restore good fluidity; when the shear is eliminated, the three-dimensional structure (hydrogen bonding) will be restored on its own, and the viscosity of the coating will increase. This characteristic of fumed silica gives oil-based coatings very good storage performance and construction performance, especially thick slurry coatings (such as marine paint), both to ensure that the coating in a certain construction shear force has good fluidity, but also to ensure that the film thickness of a construction.

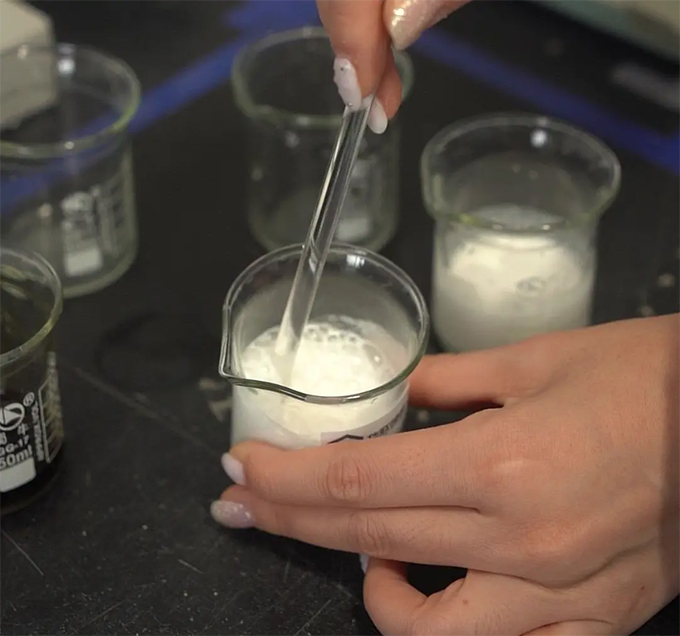

Due to its nanoscale particle size, extremely high specific surface area, and surface activity, fumed silica can rapidly adsorb onto the surfaces of pigments and fillers.This adsorption effectively reduces the interfacial energy between solid particles, thereby preventing their agglomeration. In this way, gas-phase silica promotes the uniform dispersion of pigments and fillers in liquid paint media, significantly reducing the time required for grinding and dispersion, and improving production efficiency. It ensures that the paint has better colour stability, hiding power, and uniformity of the final coating film.

Additionally, the application of silica as a dispersant is not limited to initial particle dispersion. During storage, it forms a stable three-dimensional network structure, further preventing the re-settlement and agglomeration of already dispersed particles.

For powder coatings, gas-phase silica, as an additive, effectively improves powder flowability and prevents agglomeration caused by moisture absorption during storage and transportation. By optimising interparticle forces, gas-phase silica helps maintain the long-term stability of the coating system, ensuring that the coating maintains its designed performance across various application scenarios, ultimately enhancing the overall quality and durability of the coating film.

There are a lot of silanol bonds on the surface of fumed silica, which can form hydrogen bonds with the substrate or itself, forming a similar "net" structure to "hold" the pigment or other fillers and prevent them from sinking or caking. Pyrogenic silica has a thickening effect, choose the right type of pyrogenic silica, to a certain extent, to improve the viscosity of the paint, then the pigment or filler in the process of falling by the resistance will naturally increase, can be effective in preventing the sinking or preventing agglomeration.

The surface activity of fumed silica is high, through the modified processing means, the surface charge of fumed silica can be adjusted, because in some specific coating applications, pigment or filler also exists in a certain degree of activity, which can be agglomerated or combined with each other, at this time, fumed silica can play a role in neutralisation of the charge, to prevent agglomeration or agglomerates between pigment and filler, and to further improve the storage of pigments. In powder coatings, fumed silica can be used as external additives, fumed silica particles adsorbed on the surface of the powder coatings, the paint particles blocked to promote the effect of mobility, part of the fumed silica can also play the role of moisture-proofing, to avoid the coating caking.

Coatings can extinction, is by virtue of the fumed silica has a small particle size, surface activity, purity and other characteristics, in the field of extinction coatings also have in-depth application, the specific mechanism is as follows: fumed silica particle size is small, with a certain width of the particle size distribution, can be directly applied to the extinction system; fumed silica surface activity is high, with anti-settling effect in the extinction of the field can prevent pigmentation filler settling, synergistic extinction, can also be modified into a wider particle size distribution products. Can also be modified into a wider particle size distribution of the product to use; fumed silica and most of the substrate, coating body has a small difference in the refractive index, in the extinction at the same time, the coating can be both high transparency; fumed silica as one of the fillers, can also promote coating scratch-resistant, non-slip and other functions; in addition, the spatial structure of fumed silica, for the scattering of light, absorption, dissipation, but also to promote the role of the.

The hydrophobicity of fumed silica is very important for coatings used for corrosion protection of ferrous metals. Corrosion occurs when moisture, as well as ions (e.g. sodium and calcium ions), penetrate and pass through the protective layer. The use of polar anti-sag or anti-settling agents is tantamount to providing a conduit for moisture and ions to migrate to the metal surface. Moisture that accumulates on the metal surface breaks down the adhesion of the layer, which in turn causes penetration blisters, exposing more of the metal surface and accelerating the rate of corrosion. At the same time, the presence of ions dramatically increases the ionisation intensity at the interface, accelerating the rate of corrosion. Hydrophobic fumed silica does not provide a channel for moisture and ions to migrate to the metal surface, and thus hydrophobic fumed silica reduces the extent to which osmotic blistering and corrosion occurs when compared to other types of thixotropic agents, such as treated clays, and to fumed silica that has not been treated with a full hydrophobicity treatment.

Contact: Tony Li

Phone: +86-13263299644

Tel: +86-13263299644

Email: sales@ecoviaet.com

Add: No 3 Youyi Road,Tangshan,Huantai,Zibo,China

We chat