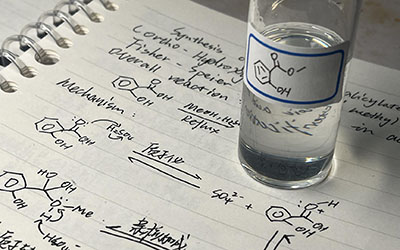

Improving the yield of esterification reactions requires careful optimization of several factors to enhance the efficiency and minimize side reactions or losses. Here are some strategies to improve esterification yields:

Sulfuric acid and trifluoromethanesulfonic acid (triflic acid) are commonly used as acid catalysts in esterification reactions because they help to protonate the carbonyl group of the carboxylic acid, making it more electrophilic and facilitating the reaction with the alcohol.

Strong acids not only catalyze the reaction but can also help in removing water from the system (especially important in equilibrium-limited reactions like esterification).

Water removal is crucial in esterification reactions as it shifts the equilibrium towards the ester formation (Le Chatelier’s principle).

Dean-Stark apparatus can be used for azeotropic distillation to continuously remove water.

Molecular sieves or drying agents (like CaCl₂) can also be added to absorb excess water.

Using anhydrous reagents (i.e., dry alcohols and acids) helps minimize the introduction of additional water into the reaction.

Increasing the temperature can help accelerate the esterification reaction by providing more energy to the molecules, facilitating the breaking of bonds and promoting faster reaction rates. However, too high a temperature can lead to side reactions or degradation of sensitive reactants, so it’s important to find the optimal temperature.

For instance, a temperature between 60–120°C is often used, depending on the reactants involved.

Excess alcohol can help drive the reaction to completion by pushing the equilibrium towards ester formation (since alcohol is part of the product). Using a large molar excess of alcohol ensures that there is enough reactant available to form the ester.

The molar ratio of carboxylic acid to alcohol should ideally be close to 1:1, but slight excess of one or the other can sometimes improve yields depending on the specific reaction conditions.

If using an excess alcohol, make sure to recover it afterward if necessary.

Adding a dehydrating agent like toluene or benzene (for azeotropic distillation) can help remove water and push the reaction towards ester formation.

Acid catalysts like sulfuric acid also act as dehydrating agents, which helps in achieving higher yields by preventing hydrolysis.

Ensure that reactants (acid and alcohol) are pure and free from impurities that could inhibit the reaction, such as water, organic acids, or other compounds that might react side-by-side with the esterification.

Refluxing the reaction mixture at the appropriate temperature ensures that the system reaches a steady state, allowing for better reaction completion.

It also allows for continuous removal of volatiles (such as alcohol vapors) while keeping the reaction components in the system.

In some cases, solvents can be used to dissolve the reactants and improve the reaction conditions. However, solvents should be chosen carefully to avoid interfering with the reaction or causing unwanted side reactions.

Non-polar solvents like toluene can help in removing water and maintaining good separation of the reactants.

For alcohols with high boiling points, the reaction can be performed under increased pressure (e.g., using a pressure vessel) to maintain a high temperature without the alcohol evaporating.

Efficient stirring or mechanical mixing can help improve contact between the reactants (carboxylic acid and alcohol) and ensure a more homogeneous reaction mixture, leading to a better yield.

Monitoring the pH of the reaction mixture can help optimize the acidic conditions. If the reaction becomes too basic (from excessive alcohol), esterification efficiency can be reduced. Keeping the mixture sufficiently acidic will maintain the desired reaction conditions.

Although prolonged reactions might seem to give better yields, excessive reaction time and high temperatures can lead to side reactions or product decomposition. After reaching a desired yield, it’s important to stop the reaction and avoid unnecessary heating.

To improve the yield of esterification, you should focus on:

Using a strong acid catalyst (e.g., sulfuric acid or triflic acid),

Continuously removing water from the reaction mixture,

Using excess alcohol and dehydrating agents,

Refluxing the mixture

Optimizing temperature, pressure, and stirring conditions.

By carefully controlling these factors, you can increase the esterification yield and reduce losses due to side reactions or incomplete conversion.

Contact: Tony Li

Phone: +86-13263299644

Tel: +86-13263299644

Email: sales@ecoviaet.com

Add: No 3 Youyi Road,Tangshan,Huantai,Zibo,China

We chat