This article will introduce the composition of electrolyte, performance requirements, hazards to humans and protective measures.

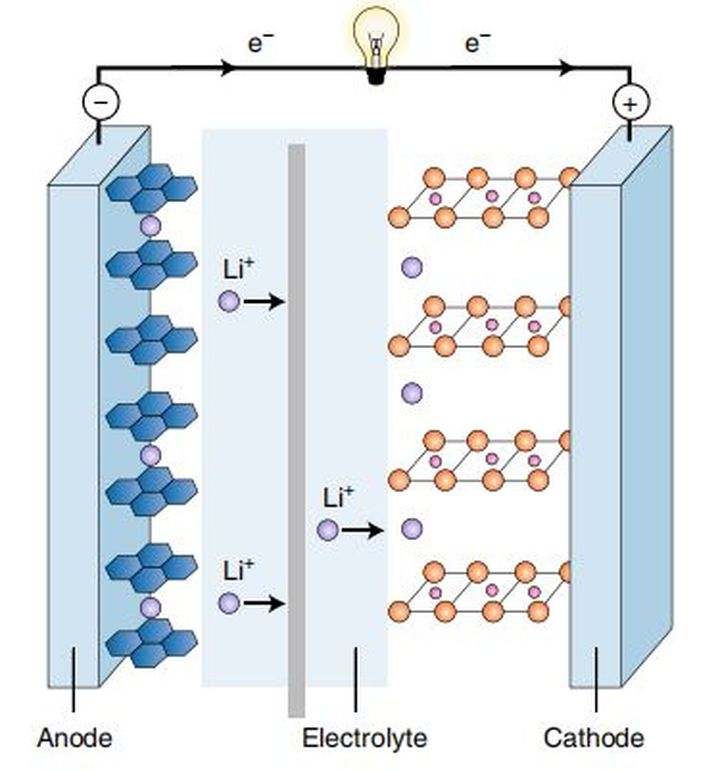

The electrolyte contains Solvents, Solutes and Additives.

Solvent: Conventional solvents are Ethylene Carbonate (EC), Propylene Carbonate (PC), Dimethyl Carbonate (DMC) and Ethyl Methyl Carbonate (EMC). New solvents are sulfite, carboxylic acid ester.

Solute: Conventional lithium salts are Lithium Hexafluorophosphate. New lithium salts are Lithium Bis(fluorosulfonyl)imide(LiFSI), Lithium Bis(oxalato)borate(LiBOB).

Additives: There are many types of additives, such as film-forming additives, overcharge protection additives, high and low temperature additives, and flame retardant additives. Each type plays a different role. Although the amount added is small, these additives have a significant impact on the performance of lithium batteries and are key to differentiating electrolyte products in the market.

The main function of the solvent in the electrolyte is to dissolve the lithium salt, which is currently mainly carbonate solvent (organic solvent). Carbonate solvents have the advantages of good electrochemical stability and high dielectric constant. We categorize carbonate solvents into Cyclic Carbonate solvents and Linear Carbonate solvents, each of which has its own characteristics.

Cyclic Carbonates include Propylene Carbonate (PC), Ethylene Carbonate (EC), and Linear Carbonates include Dimethyl Carbonate (DMC), Diethyl Carbonate (DEC), and Ethyl Methyl Carbonate (EMC). Different solvents have different properties that correspond to different battery functions. Carbonate solvents have the advantages of good electrochemical stability and high dielectric constant.

Cyclic carbonate solvents and linear carbonate solvents have different characteristics. By combining them together, we can meet specific requirements such as conductivity, operating temperature and environmental conditions. Major electrolyte manufacturers will also lay out integrated production of the main solvent system.

High-quality lithium salt solutes significantly influence the energy density, power density, broad electrochemical window, cycle life, and safety performance of lithium batteries.Lithium hexafluorophosphate (LiPF6) is currently the most widely used electrolyte electrolyte.

At present, the mainstream electrolyte lithium salt is lithium hexafluorophosphate, due to the lithium bifluorosulfonimide LiFSI chemical stability, thermal stability and high and low temperature performance are better than lithium hexafluorophosphate to get the widespread attention of the market, in view of its high cost, is mainly used as an additive, is expected with the improvement of technology and process, cost reduction, LiFSI penetration will be rapidly increased, has also become the main electrolyte industry, and has become the focus of the layout of enterprises. Layout focus of enterprises.

There are many types of additives, different additives have different roles, such as Vinylene Carbonate (VC), Fluorinated Ethylene Carbonate (FEC), etc., although the amount of additive is relatively small, but it has a greater impact on the performance effect of lithium batteries, and it is the key to the competition of differentiation of electrolyte.

| Excellent Electrolyte Performance | Impact on Battery Performance |

| High conductivity | Easy lithium ion migration, good charge/discharge capability |

| Good chemical stability | Long battery life |

| Wide operating temperature range | Ensure battery performance under high and low temperatures |

| Good safety | Key factors for the safety performance of lithium-ion batteries |

High ionic conductivity: Generally should reach 10⁻³ ~ 2 × 10⁻³ s/cm, the migration number of lithium ions close to 1;

Wide range of electrochemical stabilization potential: There must be a 0-5v electrochemical stabilization window;

Good thermal stability: Wide range of use temperature;

Chemically stable: No chemical reaction with the fluid collector and active substance in the battery;

Safe and low toxicity: No environmental pollution, preferably biodegradable.

The electrolyte poses significant health risks to the human body, with particularly adverse effects on women because of its potential toxicity, skin irritation, and long-term exposure hazards.

Electrolyte is toxic, long-term inhalation and contact will cause dizziness, nausea, vomiting and even poisoning, and in serious cases there is a risk of cancer. Electrolyte is corrosive, and if it comes into contact with the skin, it may cause pain, redness, swelling and itching.

1.Respiratory protection: Wear an activated carbon mask. If the air concentration exceeds the limit, use a self-absorbing filtering gas mask (half mask).

2.Hand protection: Wear special benzene-resistant and oil-resistant gloves.

3.Eye protection: Wear chemical safety glasses to protect your eyes from exposure to hazardous chemicals, splashes or fumes.

4.Skin and body protection: Workers must wear professional anti-static coveralls in the workplace to ensure safety.

5.After work, take a shower and change clothes, paying special attention to the protection of eyes and respiratory tract. When we dismantle batteries in our R&D work, we will come into contact with electrolyte, and we will strictly follow the above measures to protect ourselves.

Contact: Tony Li

Phone: +86-13263299644

Tel: +86-13263299644

Email: sales@ecoviaet.com

Add: No 3 Youyi Road,Tangshan,Huantai,Zibo,China

We chat